Cheap Anti-Seismic Prefabricated Buildings Workshop Price Warehouse Prefab Design Steel Structure Hall with EPS Sandwich Panel

Basic Info

| Model NO. | SH-Z01 |

| Connection Form | Bolt Connection |

| Member | Steel Column |

| Type of Steel For Building Structure | H-Section Steel |

| Carbon Structural Steel | Q235 |

| Residential Wall Structure | Wall Support |

| Application | Steel Workshop, Steel Structure Platform, Steel Fabricated House, Structural Roofing, Frame Part, Steel Walkway and Floor, Steel Structure Bridge |

| Keyword | Prefab Steel Structure Build Warehouse |

| Main Frame | Q345 Q235 Steel |

| Delivery Time | Around 25days |

| Installation Guide | Installation Drawings, Engineer Helps to Instruct |

| Surface Treatment | Galvanized or Painted |

| Types | Light Frame |

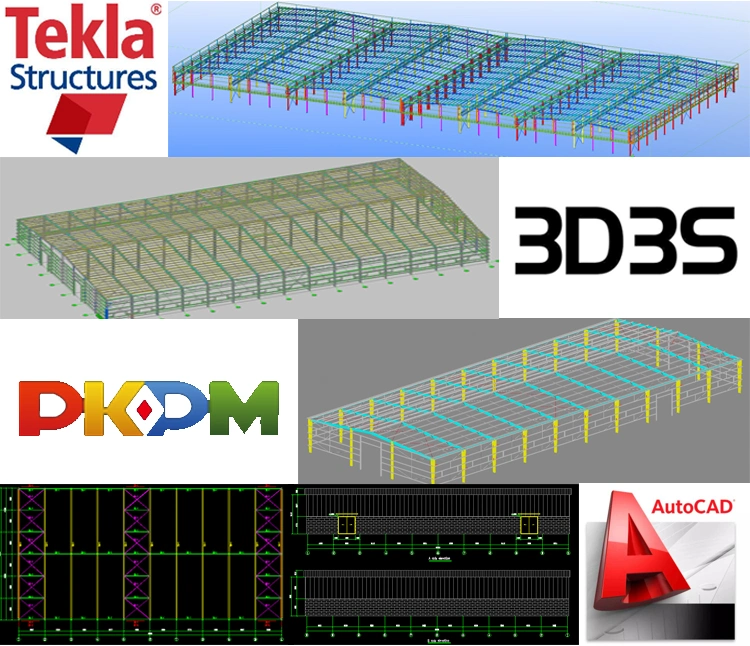

| Drawing Design | Autocad, 3D3s, etc |

| Technology | Welded Steel, Hot Rolled Steel |

| Applications | Warehouse, Workshop, Hangar, Shed, Poultry Farm |

| Door | Sandwich Panel, Roller up Door |

| Transport Package | Nude Packing |

| Specification | 25m*60m*6m prefab steel structure build warehouse |

| Origin | China |

| HS Code | 73089000 |

| Production Capacity | 2500t Per Month |

Product Description

Prefab Construction Materials Prices Steel Structure Build Warehouse

Why choose prefab steel structure build warehouse?

1. Short construction period: Compared with the traditional concrete structure, the construction period forprefab steel structure build warehouse is about 1/3 shorter than the traditional concrete structure

2. Improve investment efficiency: Short construction period can reduce the pressure of capital occupation,reduce the risk of market change, and improve the investment efficiency of prefab steel structure build warehouse.

3. Reduce foundation cost: The requirement of prefab steel structure build warehouse on foundationload is reduced, which can greatly reduce foundation cost and civil foundation cost.

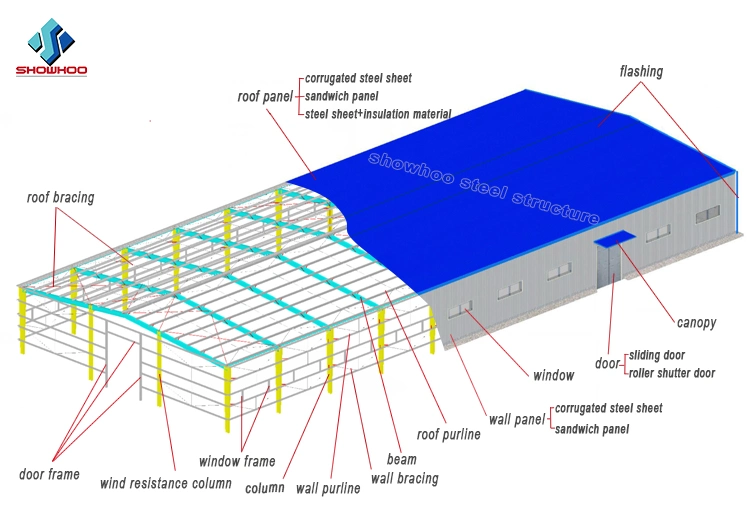

Prefab steel structure build warehouse structure show:

Related components for prefab steel structure build warehouse?

| Steel Structure Parts:(Q235 or Q355) Hot galvanized or painted | (1). Steel Column: H Section Steel |

| (2). Steel Beam: H Section Steel | |

| (3). Withstand Wind Column: H Section Steel | |

| (4). Connected beam: Circular Tube | |

| (5). Roof Purline:cold formed galvanized C Section Steel or Z Section Steel | |

(6). Wall purline: cold formed galvanized C Section Steel or Z Section Steel | |

| (7). End Wall purline: C Section Steel or Z Section Steel | |

| Panel Material parts | (1). External Wall panel: (below is selectable) |

| 1) 50mm, 75mm or 100mm thickness EPS sandwich panel | |

| 2) 50mm, 75mm or 100mm thickness Rockwool sandwich panel | |

| 3) 50mm, 75mm or 100mm thickness PU OR FIBER GLASS wool sandwich panel | |

| 4)Corrugated Galvanized Steel sheet with different Color | |

| (2). Internal Wall panel: (below is selectable) | |

| 1)50mm, 75mm or 100mm thickness EPS sandwich panel | |

| 2) 50mm, 75mm or 100mm thickness Rockwool sandwich panel, fiber glass wool sandwich panel or PU sandwich panel | |

| (3). Roofing panel: (below is selectable) | |

| 1)50mm, 75mm or 100mm thickness EPS sandwich panel | |

| 2)50mm, 75mm or 100mm thickness Rockwool sandwich panel | |

| 3)Corrugated Steel Sheet, and insulating layer if need. | |

| 4) 50mm, 75mm or 100mm thickness fiber glass wool or PU sandwich panel | |

| (4). Skylight: 820# Glass Fiber Reinforced Plastics (FRP) | |

| Door and Window | (1). External Door ( Rolled up door or Sliding door ) |

| -1. Sandwich panel Sliding Door with double open | |

| -2. Galvanized steel opening by power-operated Roller Door | |

| (2). Internal Door: | |

50mm Thickness EPS sandwich panel with aluminum alloy door frame | |

| (3). Window: | |

| PVC Window or aluminum alloy window frame with glass. | |

| Drainage parts | (1).Galvanized water channel: |

2mm thickness galvanized steel water channel @ 3000mm or 2440mm/pcs | |

| (2). Down spout: ∅110 PVC Down spout with Accessorie | |

| Connecting Piece | (1) Purline draw bar: ∅12 |

| (2) Horizontal Bracing: ∅24 Circular Tube | |

| (3) Knee-Bracing: L Steel | |

| (4) Purline Drive pipe: Φ32*2 | |

| (5) Column Bracing: ∅24 Circular Tube |

There are 4 options of installation as following:

1. Clients install it by themselves according our drawings and simple video.

2. Our engineer help our client to install on construction site.

3. We provide installation team to help.

4. Our client arrange their engineer to visit our factory and learn how to install from our engineer.

Only we get the following details, we could offer you the best price soon.

| Size | length, width, eave height and ridge height? |

| Climate | wind speed, snow load, temperature, which city will you build in? |

| Roof panel material | EPS sandwich panel, fiber glass wool sandwich panel, rock wool and PU sandwich panel, or corrugated steel sheet, which you like more? |

| Wall panel material | EPS sandwich panel, fiber glass wool sandwich panel, rock wool and PU sandwich panel, or corrugated steel sheet, which you like more? |

| Window or door | The size and quantity, any special requirement please? |

| Steel frame | H/C section steel frame or Z section steel frame? hot galvanized or painted steel frame please? |

| Other need or not | Gutter, downpipe, skylight, fans, or whether there is a crane? if yes, what's the loading weight of the crane? |

Qingdao Showhoo Steel Structure is an ISO 9001:2008 Certified manufacturer of Prefab ConstructionMaterials Prices Steel Structure Build Warehouse based in Qingdao, China, started 2000. Spreadover 30,000sq meters and having fully atomatic machinery and high qualified design, engineering, fabrication& erection staff.

It has 5 production line of H section steel with 20,000 T annual production, 2 production lines of C&Z sectionsteel with 16,000T annual production, yearly production exceeds 2 milllion meters corrugated steel sheet andsandwich panel with 5 production lines.

Showhoo is geared up to handle all kinds of projects, including prefab steel structure build warehouse,prefab steel frameworkshop, hangar, poultry house, barn, etc.

FAQ:

Q1: You are manufacture factory or trading company?

A: We are manufacture factory and welcome you to visit our factory, so you can enjoy factory price and inspectthe quality before delivery.

Q2: How do you ensure your quality?

A: One side,we have a strict quality control system in our factory, which conforms to the ISO9000 qualitycertification system. The other side, we support the inspection before shipment by SGS,BV CCIC and othercertification company.

Q3: Where have you been exported ?

A: Up to now, We have exported to South Korea, Malaysia, Kampuchea, Kuwait, Australia, Argentina, Chile, Bolivia,Nepal, Ghana, Benin, Mauritius, Qatar etc, with good quality and best price ,good after-sale service to win customers trust.

We have 3 years warranty for the quality problem of our goods. If you have any requirement for prefab steel structure build warehouse or other related steel structure project, you could directly click the following " send " button,we will give you answer soon.